R&D center

TCS is committed to advancing flame-retardant fabric technology to secure the world’s top fabric expertise.

Through research and development, we create the highest quality fabrics, manufacturing products

that enhance everyday life.

Eco-Friendly Flame-Retardant

Fabric Technology Process

- No flame-retardant yarn used

- Same process as regular yarn manufacturing

01 Yarn

- Same weaving method as before

- Flame-retardancy maintenance technology

02 Weaving / Knitting

- No flame-retardant agents used

- No harmful substances produced

03 Dyeing / Finishing

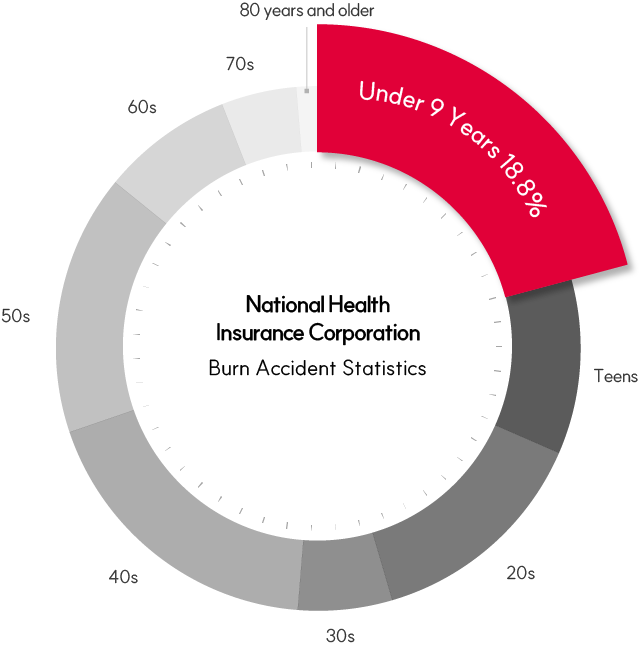

The need for

Flame-Retardant fibers

In the event of a fire, not only is the initial damage significant, but the secondary damage

caused by toxic gases released from burning building materials and textiles can be immense.

This has led to movements advocating for the establishment of new regulations and the strengthening

of existing regulations to expand the use of flame-retardant materials.

Therefore, it is crucial to use building materials that comply with fire safety regulations, adhere to safety

standards, and utilize flame-retardant fabrics in interior spaces such as curtains to minimize fire hazards.

Fire Accident Prevention

Fire Accident Prevention

- - 2015 Glamping site fire incident

- - 1999 Incheon pub fire resulting in 50 fatalities

- - Daegu subway accident with over 130 fatalities, etc.

For residential spaces, wall coverings

For residential spaces, wall coverings

and children’s sleepwear should use

flame-retardant fabrics

that are not easily ignited

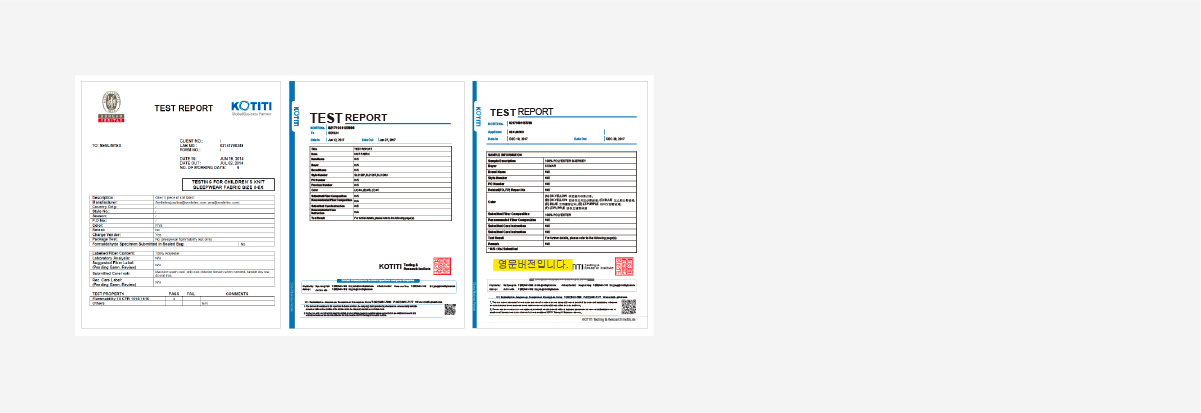

CERTIFIED

This is a certification related to eco-friendly flame-retardant fabric technology processes.

We use tightly woven 100% premium 20s single jersey fabric to ensure comfortable wear.

The surface is treated with non-harmful chemicals to provide a soft and flexible finish.